- Home

- About Us

- Shop

- Service and Support

- Media

- Contact Us

- Home

- About Us

- Shop

- Service and Support

- Media

- Contact Us

We specialize in ...

Trusted by boaters around the world for Reliable, Clean Water for 30+years

Sales, Service & Installation

FCI Watermakers Have Been Cruising the Globe for Decades

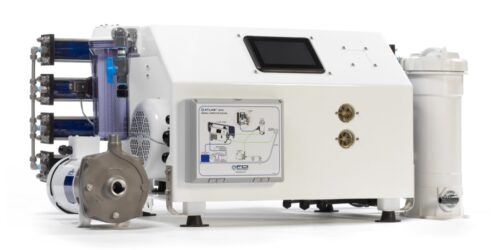

FCI Watermakers does more than build and sell marine reverse osmosis systems. We invent the technology and advance the systems that are the future of marine desalination around the planet.

- Industry's Quietest

- Purer than tap water

- More for your money

- Extensive Testing

- 1 year Warranty

- Committed customer service

Reverse Osmosis with Exclusive and Uncompromizing Engineering

Watermakers For Your Boat

INDEPENDENT & RELIABLE SUPPLY

Secure fresh water today,

without limiting tomorrow, independent of others.

STRESS FREE OPERATION

The industry’s most advanced watersmart intelligence does the work for you.

COMMITTED PARTNER

Exceeding expectations – through the quality of our products, commitment, and your success.

INNOVATIVE ENGINEERING

Intuitive engineering guarantees the longevity, durability, and performance of every system.

Commercial Prefilter

Commercial quality filtration is standard with our commercial pre-filter housing and pleated 5 micron filter

Sure-Touch Operation

Reliable tactile feedback from FCI’s watermaker control panel eliminates operator error and provides automatic programming with at-a-glance monitoring. The tried and true technology and digital displays are resilient to all boating conditions, unlike touchscreens that potentially fail in high-temperature climates or engine rooms. The FCI V4 Controller Technology leads the market with complete automation and Marine certifications

Noise Control

Engineering the industry’s only frame with eight-point vibration isolation, our watermarking systems are quiet due to its open frame construction, eight-point isolating mounts and low RPM high-pressure pump. Competing systems amplify noise due to closed-frame construction and high-pressure pumps running at double the RPMs which creates a systemic, throbbing resonance throughout the vessel.

Low Pressure Pump

Designed to withstand wet marine environments, FCI’s washdown duty motor is conditions and usage. Epoxy coated with neoprene gaskets and 316 stainless steel shafts that protect it from moisture, rot and rust. FCI motors will outlast competing brands, which use inferior general or industrial duty motors with lesser features, like painted housing, paper gaskets and standard steel shafts

Superior Materials

Industrial-quality materials ensure the durability and longevity of every FCI watermaker. Our systems are engineered with durable parts made from quality metals like 316L stainless steel, instead of plastic which provides strength and reliable operation by preventing corrosion as well as undo wear and tear.

Pressure Vessels

FCI is so confident of the superiority of our engineering that we offer a lifetime warranty on every pressure vessel tube and have never yet had a claim. Four 316L stainless steel rods surround the vessel, while ports are specifically designed to flex and move with the pressure to remove stress. FCI’s watermakers feature a superior end plug design that prevents loosening, leaks, cracking and salt water crystallization due to natural vibration and water pressure.

Membranes

While all of our marine systems designs are engineered to be compatible with standard size membranes, allowing for readiness and ease of use for our customers no matter where they are, we manufacture and ship our membranes composed of the same high-quality materials and fabrication our products

are known for. These membranes are best matched with our watermaker’s engineering performance specifications and provide the highest water quality and increase membrane performance.

Fresh Water Flush included

Fresh water flush is a standard feature in FCI marine systems from 250 gallons per day (GPD) to 3,600 gallons per day (GPD). While most competing brands consider this function an accessory and extra charge, FCI believes in providing a comprehensive system that offers optimal performance.What’s more, with our V4 Control System, your fresh water flush is automatic and fully programmable—you control the frequency and duration to suit your needs under divergent water

High / Low Pressure Transducer

FCI’s 316L stainless steel transducers offer users multiple function settings and continuous digital readouts. The user can customize the system to meet specific needs and effectively monitor the operation of the system during use. Many other brands use switches instead of transducers, which limit a user’s regulation to “on” and “off” functions only.

Get A Free Quote For Your Project

Feel free to contact us and get a free quote